جهت مشاوره تخصصی رایگان با ما درتماس بگیرید...

تولید گلوله آسیا یا آسیاب به روش فورج

گلوله آسیا (گلوله آسیاب)

گلوله آسیا (گلوله آسیاب) عامل خردایش مواد در آسیاب ها می باشند. در انگلیسی به آن ها GRINDING BALLS می گویند. این قطعات ضد سایش با حرکت خود در آسیا و ریزش پیوسته به خردایش مواد یا میکرونیزه شدن آن کمک می کنند. امروزه تناژ ، سایز و آنالیز شیمیایی و خواص تمام شده آن می باشد. این محصولات در سایز های مختلف تولید شده و این تنوع گسترده از سایز می تواند دامنه وسیعی از دانه بندی را در محصولات آسیا ایجاد کند.

نکات استفاده از گلوله آسیا

یکی از موارد مهم هنگام استفاده از گلوله ها نرخ سایش گلوله ها می باشد. هرچه قدر میزان سایش آن ها کمتر باشد، گلوله ها دیرتر نیاز به تعویض پیدا می کنند و این از نظر اقتصادی بسیار با اهمیت است. این گلوله ها در دو نوع با درصد کروم کم و زیاد تولید می شود. گلوله آسیا با نام های دیگری از جمله گلوله فلزی و گلوله بالمیل و گلوله آسیاب نیز شناخته می شوند.

مقاله پیشنهادی ما ریخته گری قطعات

گلوله آسیا یا توپ های آسیاب، نحوه توزیع و استفاده

گلوله آسیاب (گلوله بالمیل) یکی از اجزای مهم فرآیند سایش در صنعت هستند که معمولاً از فولاد، فولاد، چدن، آلومینیوم و … ساخته می شوند. در این مقاله با ما همراه باشید تا در مورد Ball Factory بیشتر بدانید. توپ هایی با ابعاد و مواد مختلف مانند فولاد، فولاد، چدن و آلومینیوم طراحی و ساخته می شوند. این توپ ها در فرآیند سایش در آسیاب های گلوله ای استفاده می شوند و بسیار مهم هستند.

کاربرد اصلی توپ های آسیاب یا گلوله آسیا ، سایش و تمیز کردن مواد معدنی مانند مس، سرب، روی، آهن، سیمان، سیلیکات، سیمان، مصالح ساختمانی و سایر کانی های فلزی و غیرفلزی است، اما کاربرد های دیگر آن شامل توپ های آسیاب می باشد.

کاربرد گلوله آسیا در آسیاب گلوله ایی

کاربرد گلوله آسیا را در صنایع مختلف می توانید مشاهده کنید. صنایع مخالف از گلوله بالمیل کوچک و بزرگ به منظور آسیاب و مخلوط کردن مواد استفاده می شود. برخی از کاربرد های آسیاب گلوله ای در صنایع سیمان ، معدن ، داروسازی ، غذایی ،سرامیک و… می باشد.

به طور کلی، آسیاب بالمیل ماشین های همه کاره ای هستند که می توانند برای کاربرد های مختلف در صنایع مختلف مورد استفاده قرار گیرند، جایی که مواد باید آسیاب و مخلوط شوند تا به یک اندازه ذرات خاص یا سایر خواص فیزیکی برسد.

آسیاب گلوله ای نوعی آسیاب صنعتی است که برای تولید پودر ریز یا همگن کردن مخلوط استفاده می شود. در آسیاب گلوله ای، از گلوله های فلزی یا گلوله آسیا (بال میل) یا سرامیکی برای آسیاب و صاف کردن مواد غیرفلزی استفاده کنید.

عمده کاربردهای این نوع آسیاب در تولید رنگ، سرامیک، سیمان و مواد شیمیایی می باشد. در این نوع آسیاب از تعداد زیادی توپ فلزی (گلوله آسیا ) یا سرامیکی استفاده می شود که به نرمی روی یکدیگر حرکت می کنند و با هم زدن یا چرخاندن آسیاب، دانه های درشت را می شکنند.

| یکی از کاربرد های گلوله فولادی آهنگری در آسیاب های گلوله ای است که در آن به سایش شدید و مقاومت شیمیایی نیاز است. |

| گلوله آسیابی همچنین می توانند در مواردی که تولید گرما برای فرآیند های رنگرزی و پراکندگی مهم است استفاده شوند. |

| از آسیاب بالمیل تا آسیاب سریع و بدون آلودگی (تر یا خشک) جامدات، پراکندگی مایعات و خرد کردن ذرات ریز، همگن سازی پرکننده ها و مواد اولیه استفاده می شود. |

| کاربرد های ساینده و تکمیل کننده در آسیاب های گلوله ای، اسلاید، دینو، آسیاب، افقی یا عمودی است. |

| گلوله آسیابی یا گلوله بالمیل چگالی و سختی بالایی دارد که باعث می شود در فرآیند خرد کردن و اختلاط مواد سخت بسیار مفید باشد. |

| گلوله های فرز در آسیاب هایی که در معرض ارتعاشات و فشار قوی هستند استفاده می شود. |

| این گرانول ها در کاهش اندازه ذرات و پخش مایعات با ویسکوزیته بالا بسیار موثر هستند. |

| گلوله های کربن در آسیاب های کم سرعت مانند آسیاب های پودر متالورژی و شیمیایی استفاده می شود. |

| آسیاب های با سرعت بالا مانند رنگ، جوهر و پودر رزین از توپ های فولادی سطحی استفاده می کنند زیرا قوی تر و قوی تر هستند. |

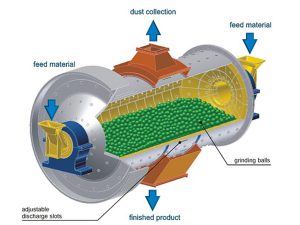

آسیاب گلوله ای از یک استوانه توخالی تشکیل شده است که حول یک محور افقی یا با زاویه کوچکی نسبت به افق می چرخد. سنگ زنی با توپ های ساخته شده از فولاد (فولاد کروم)، فولاد ضد زنگ، سرامیک یا لاستیک انجام می شود. سطح داخلی سیلندر معمولا با مواد مقاوم در برابر سایش مانند فولاد منگنز یا لاستیک پوشیده شده است. طول آسیاب تقریباً برابر قطر آن است.

مراحل تولید گلوله آسیا

توزیع اندازه گلوله بالمیل در آسیاب گلوله

سرعت آسیاب عامل اصلی تعیین کننده توزیع گلوله ها در هنگام سایش است و بنابراین سرعت آسیاب، اندازه گلوله آسیا را نیز انتخاب می کند. به عنوان مثال، در یک آسیاب با سرعت پایین، گلوله های بزرگ در اطراف بار و در یک آسیاب با سرعت بالا در وسط جمع آوری می شوند.

دلیل این جدایی این است که در سرعت های پایین، گرانش قوی تر از نیروی گریز از مرکز است، بنابراین ابزار سنگ زنی به سمت مرکز مخلوط در آسیاب حرکت می کند.

علاوه بر این، اجزای بالمیل داخل آسیاب نیز بر نتایج عملیات تأثیر میگذارد، زیرا با چرخش آسیاب، ذرات کوچک تر شروع به حرکت به سمت مرکز میکنند و ذرات بزرگ تر در بالا جمع میشوند. بهترین راه برای ترکیب ذرات، داشتن یک اندازه گلوله آسیابی ثابت در سرتاسر شارژ برای به حداکثر رساندن تماس بین ذرات است. همچنین اگر راندمان آسیاب بال میل افزایش یابد، می توان از کل چیز های آسیایی کم کرد.

مقاله ی پیشنهادی ما قطعات ضدسایش

یا بالمیل

شرکت متالورژی مصمم ( تولید کننده گلوله های آسیاب ) در زمینه فروش گلوله بالمیل فعالیت دارد. ابعاد گلوله آسیا از سایز 25mm تا 125mm موجود می باشد.در ادامه به بررسی ابعاد گلوله آسیاب می پردازیم.

آسیاب برای آسیاب موادی مانند زغال سنگ، رنگدانه ها و فلدسپات برای سرامیک استفاده می شود. تنها در صورتی که آسیاب با سرعت کم انجام شود، مواد آسیاب را می توان جدا یا خنک کرد. به عنوان مثال، مخلوط کردن مواد منفجره توسط یک آسیاب با گلوله های لاستیکی انجام می شود. برای سیستم های چند جزئی، روش آسیاب گلوله ای نشان داده شده است که واکنش شیمیایی را در فاز جامد افزایش می دهد.

آسیاب گلوله ای

آسیاب گلوله ای نوعی آسیاب استوانه ای است که برای آسیاب یا مخلوط کردن موادی مانند مواد معدنی، مواد شیمیایی، مواد خام سرامیکی و مواد غیر آهنی استفاده می شود. آسیاب های گلوله ای از موادی که قرار است آسیاب شوند پر می شوند و گلوله آسیا پر می شوند و حول یک محور افقی می چرخند.

حرکت آبشاری گلوله های آسیا یا گلوله آسیاب در داخل استوانه و افتادن آنها بر روی ماده منجر به بدست آوردن پودری به اندازه دلخواه می شود. آسیاب های گلوله ای صنعتی این قابلیت را دارند که به طور مداوم کار کنند و از یک انتها وارد و از سر دیگر خارج شوند. دستگاه بالمیل بزرگ و متوسط به صورت مکانیکی حول محور خود می چرخند، اما انواع کوچکتر معمولاً از یک استوانه روکش دار تشکیل شده است که بر روی دو محور متحرک نصب شده است.

جنس گلوله ها (گلوله آسیا یا بالمیل)

همانطور که گفته شد، گلوله بالمیل معمولاً از آلومینیوم، چدن یا فولاد آهنگری ساخته می شوند. برای ایجاد ویژگی های دیگر در گلوله آسیاب می توان آنها را از مواد دیگری ساخت، به عنوان مثال می توان گلوله ها را از فولاد خامه ای یا کروم مولیبدن ساخت تا در برابر سایش مقاوم تر شوند. انتخاب نوع گلوله بستگی به نوع کار و امکانات صنعتی دارد، به عنوان مثال:

| گلوله های چدن برای کوره های چدن استفاده می شود. |

| برای جرم سوزاننده از گلوله های چدن سخت مقاوم در برابر خوردگی استفاده می شود. |

| سنگ های عقیق یا توپ های سرامیکی برای جلوگیری از ورود آهن به مخلوط خرد شده استفاده می شود. |

آسیاب گلوله ای در صنعت تجهیزات آتش بازی برای تولید پودر سیاه استفاده می شود، اما نمی توان از آن برای ساخت مواد آتش بازی مخلوط مانند پودر فلاش استفاده کرد. زیرا این مواد در برابر ضربه بسیار حساس هستند. آسیاب های گلوله ای با کیفیت بالا به طور بالقوه گران هستند و می توانند مخلوط را تا ذرات 5 نانومتری آسیاب کنند و سطح تماس و واکنش پذیری را به طور چشمگیری افزایش دهند.

سنگ زنی بر اساس اصول سرعت بحرانی انجام می شود. سرعت بحرانی سرعتی است که در آن توپ ها به دیواره سیلندر می چسبند و با آن حرکت می کنند و سانتریفیوژ متوقف می شود. بنابراین، فرآیند سنگ زنی قطع می شود. آسیاب های گلوله ای به طور گسترده در پردازش آلیاژ های مکانیکی استفاده می شود.

در این روش از آسیاب گلوله ای نه به عنوان آسیاب، بلکه به عنوان ابزاری برای ایجاد جوش سرد بین ذرات پودر و تشکیل آلیاژ استفاده می شود. آسیاب گلوله ای یکی از تجهیزات اصلی مورد نیاز برای آسیاب کردن مواد خرد شده است. همچنین در خط تولید انواع پودر ها مانند سیمان، سیلیکات، نسوز، کود، شیشه سرامیک و … کاربرد فراوانی دارد.

دستگاه بالمیل در صنعت فرآوری سنگ فلزات آهنی و غیرآهنی استفاده می شود. آسیاب گلوله ای می تواند انواع مواد معدنی و مواد را به صورت مرطوب و خشک آسیاب کند. موادی که در آسیاب گلوله ای آسیاب می شوند می توانند متفاوت باشند و بر این اساس تقسیم می شوند. هر نوع ساینده خواص و مزایای خاص خود را دارد. خواص اصلی مواد سنگ زنی اندازه، چگالی، سختی و ترکیب است.

| اندازه: هرچه اندازه مواد آسیاب کوچکتر باشد، پودر حاصل کوچکتر خواهد بود. لازم به ذکر است که اندازه توپ ها باید به طور قابل توجهی بزرگتر از اندازه ذرات مواد آسیاب باشد. |

| چگالی : گلوله ها (گلوله آسیا ) باید متراکم تر از مواد ورودی باشند. زیرا به سختی گلوله ها روی مواد ورودی شناور می شوند. |

| سختی: ساینده ها باید به اندازه کافی دوام داشته باشند تا مواد خوراک را آسیاب کنند، اما نه آنقدر سخت که پوشش را با سرعت بالا آسیاب کنند. |

| ترکیب: الزامات خاصی برای کاربردهای کششی مختلف وجود دارد. برخی از این الزامات با توجه به میزان مواد پرکننده در محصول نهایی تعیین می شود. شرایط باقیمانده بر اساس واکنش مواد آسیاب با مواد ورودی است. |

| در مواردی که رنگ محصول نهایی مهم است باید به رنگ گلوله آسیاب (گلوله بالمیل) نیز توجه شود. |

در مواردی که آلودگی جزئی است، مواد گلوله باید به گونه ای انتخاب شود که بتوان آن را به راحتی از محصول نهایی جدا کرد (به عنوان مثال، گلوله فولادی از گلوله فولادی ضد زنگ به راحتی توسط آهنربا از محصولات غیر آهنی جدا می شوند). آیا استفاده از گلوله از همان نوع محصول نهایی است.

مواد قابل اشتعال به شکل پودر می توانند منفجر شوند. گلوله های فولادی ممکن است باعث آتش گرفتن محصول شوند. در چنین مواردی، مواد آسیاب باید به گونه ای انتخاب شود که جرقه نداشته باشد (مانند سرامیک یا قلع) یا از آسیاب بالمیل مرطوب استفاده شود.

برخی از مواد قابل بازیافت مانند فولاد ممکن است با مواد مضر واکنش دهند. به همین دلیل، فولاد ضد زنگ و سنگ چخماق به عنوان مواد گلوله ای ترجیح داده می شوند که موادی وجود داشته باشند که در فرآیند سنگ زنی آسیب ببینند.

انواع گلوله های آسیا

| توپ های فولادی ضد زنگ | این نوع گلوله (گلوله آسیاب) دارای انواع فولاد های زنگ نزن مارتنزیتی و آستنیتی می باشد و به دلیل خاصیت ضد خوردگی آنها در مواقعی استفاده می شود که حفظ یکپارچگی گلوله نهایی در محیط خورنده مهم باشد. |

| توپ های فولادی مارتنزیتی | اینها کره های فولادی ضد زنگ (12٪ کرم) هستند که در طول سخت شدن ساختار مارتنزیتی پیدا می کنند و مقداری مقاومت در برابر خوردگی را از دست می دهند، اما از نظر خواص مکانیکی از فولاد زنگ نزن آستنیتی پیشی می گیرند. آنها انتخاب خوبی برای یاتاقان ها و شیرها هستند. |

| توپ از فولاد ضد زنگ آستنیتی | این نوع گلوله ها فولاد های ضد زنگ غیر مغناطیسی با نیکل بالا و کرم های ساختار آستنیتی هستند که سختی فولاد های تصفیه شده با آب را ندارند، اما دارای خواص ویژه ای مانند مقاومت در برابر خوردگی بالا، خواص مکانیکی خوب و شکل پذیری بالا هستند. از این نوع گلوله در شیرآلات و تجهیزات مشابه استفاده می شود. |

| گلوله های پلاستیکی | توپ های پلاستیکی بسیار سبک هستند و وزن آنها از 1 تا 1.2 گرم است. ساینده های پلاستیکی دارای اشکال مکعبی یا کروی با ابعاد از 150 میکرون تا کسری از اینچ هستند و معمولاً در تفلون ها و همچنین در میله ها و توپ های با روکش تفلون استفاده می شوند. همچنین جنس این نوع توپ زمینی معمولاً از پلی استایرن، پلی آمید، پلی کربنات یا اکریلیک می باشد. |

| شیشه شات | از گلوله های شیشه ای در کار های مهندسی و تزئینی استفاده می شود و در گذشته در جاهایی که از ماسه برای عملیات تراشیدن استفاده نمی شد، از این گلوله ها به اندازه دانه های تسبیح استفاده می شد. وزن این گلوله ها حدود 2.2 تا 3 گرم است. این دانه های شیشه ای حاوی انواع سرب، بدون کربنات سدیم، بوروسیلیکات، قلیایی ضعیف و غیره هستند و در اندازه های یک میکرون تا ۲ اینچ تولید میشوند.

شیشه ها از نظر گردش مناسب و خواص سایش یکی از بهترین مواد با عملکرد سایش هستند. علاوه بر این، از آنجایی که دانه های شیشه ای در اندازه های خاص موجود هستند، می توان از آنها در سیستم های جداسازی نوری مانند طیف سنج ها برای دستگاه های الکترونیکی خاص استفاده کرد. |

| ساینده توپ آلومینا | این نوع توپ های اکسترود شده در اندازه های 400 میکرون تا بیش از یک سانتی متر به صورت دانه ای، کروی، کروی (گلوله و نواری) و استوانه ای و در تراکم های مختلف بسته به رشد فاز Al2O3 ساخته می شوند. همچنین وزن کل این گلوله ها از 2.8 تا 3.9 گرم و قیمت آنها نسبتاً ارزان است.قسمت کسری این نوع گلوله ها که آلومینا است در فاز SiO2 ذخیره می شود. |

| توپ زیرکونیایی | سیلیکات زیرکونیوم را برش دهید اکسید زیرکونیوم با چگالی بالا |

محفظه سنگ زنی را می توان با یک گاز بی اثر به عنوان محافظی پر کرد که با مواد سنگ زنی واکنش نشان نمی دهد. این از اکسید شدن یا انفجار محصول در گاز اطراف جلوگیری می کند. گلوله آسیا سخت شده برای آسیاب های گلوله ای که نیاز به سایش شدید و مقاومت شیمیایی دارند ایده آل هستند .

علاوه بر این، گلوله های آسیابی را می توان در مواقعی استفاده کرد که فرآیند های اتلاف حرارت و کشش مهم هستند آلودگی جامد گلوله های کروی و فولادی (تر یا خشک) در آسیاب های سریع، پراکندگی مایع و کاهش اندازه ذرات ریز، تثبیت پرکننده و مواد خام، کاربرد های توپ، لغزش، دینو، آسیاب در آسیاب های غلات، در حالت افقی یا عمودی.

فولاد های آلیاژی به دلیل چگالی و سختی نسبی بالا، کاربرد های خاصی در سنگ شکن ها و اختلاط مواد سخت و سنگین دارند. علاوه بر این، این نوع فولاد در آسیاب که فشار و ضربه بالا اعمال می شود و یا در فرآیند های مختلف خرد کردن سنگ مورد استفاده قرار می گیرد. گلوله بالمیل تولیدی دارای مزایای زیادی در کاهش اندازه ذرات و پراکندگی ریز مایعات بسیار ویسکوز هستند.

به طور کلی، توپ های کربن فولادی برای آسیاب گرانول های کم سرعت مانند آسیاب فلزات یا پودر های شیمیایی استفاده می شود. فرآیند های آسیاب گلوله ای با سرعت بالا که در تولید رنگ، رنگدانه یا پودر رزین مورد استفاده قرار می گیرند، به دلیل استحکام و دوام بالا، معمولاً از توپ های فولادی آلیاژی کرم استفاده می کنند.

آسیاب گلوله ای به طور کلی چندین مزیت دارد : هزینه نصب و سنگ زنی مواد کم است. برای تولید دسته ای و مداوم، ظرفیت بالا و همچنین آسیب دیدگی مدار باز و مدار بسته مناسب است و همچنین برای تمامی مواد با هر درجه سختی قابل استفاده است.

به غیر از آسیاب های گلوله ای معمولی، نوع دومی نیز وجود دارد که به آسیاب های گلوله ای سیستمی نیز معروف است. این نوع آسیاب کوچکتر از نوع معمولی است و در آزمایشگاه ها برای آسیاب مواد نمونه در اندازه های بسیار کوچک استفاده می شود. یکی دیگر از کاربرد های گلوله آسیابی ، شفت ماشینی است.

یک سیستم آسیاب بالمیل حداقل از یک محفظه سنگ زنی تشکیل شده است که به شیوه ای غیر عادی چیده شده است و به آن چرخ خورشیدی می گویند. جهت حرکت چرخ خورشید برخلاف جهت حرکت اتاقک های آسیاب است. توپ های آسیاب (گلوله آسیا یا گلوله آسیاب) تحت حرکات چرخشی مختلفی قرار می گیرند (به نام نیروهای کریولیس).

خرید گلوله آسیا

شرکت مصمم آمادگی تولید انواع گلوله های آسیا را با بهترین کیفیت دارد. برای خرید گلوله آسیاب و دریافت قیمت گلوله فولادی بالمیل با ما تماس بگیرید یا با پر کردن فرم تماس، منتظر تماس کارشناسان ما باشید.همچنین می توانید برای مشاوره ی تخصصی رایگان خرید گلوله آسیاب با کارشناسان متالورژی مصمم در ارتباط باشید.

سوالات متداول در مورد گلوله آسیاب ؟

1.خرید گلوله آسیاب از متالورژی مصمم چگونه است؟

خرید گلوله آسیاب از متالورژی مصمم می توانید با شماره ی 09136575020 تماس بگیرید.

2.گلوله بالمیل با گلوله آسیاب یکی است؟

گلوله بالمیل نام دیگر گلوله آسیاب می باشد.شایا به ذکر است گلوله آسیاب با نام های گلوله آسیا، گلوله فلزی، گلوله بالمیل، گلوله فولادی و گلوله آسیاب نیز معروف است.

3.مراحل تولید گلوله آسیا یا آسیاب چیست ؟

1. تایید واحد کنترل کیفیت

2. وارد شدن مواد به کارخانه

1.ذوب مواد اولیه

2. تزیق مواد اولیه

3. قالب گیری